How to Find the Real Reason Your Growth Is Slowing Down

And how to fix it without rebuilding everything

You’re working hard.

Your team is smart.

But something’s slowing you down — and you can’t quite explain what.

Projects take longer.

You’re chasing updates more often.

And despite all the effort, progress feels… stuck.

If this sounds familiar, you’re not alone.

Many companies hit this point.

The question is: what’s actually causing it?

The Hidden Bottleneck

Every business is a system — a mix of people, tools, and processes working together to produce outcomes.

And in every system, there’s always one constraint — a single point that holds everything else back.

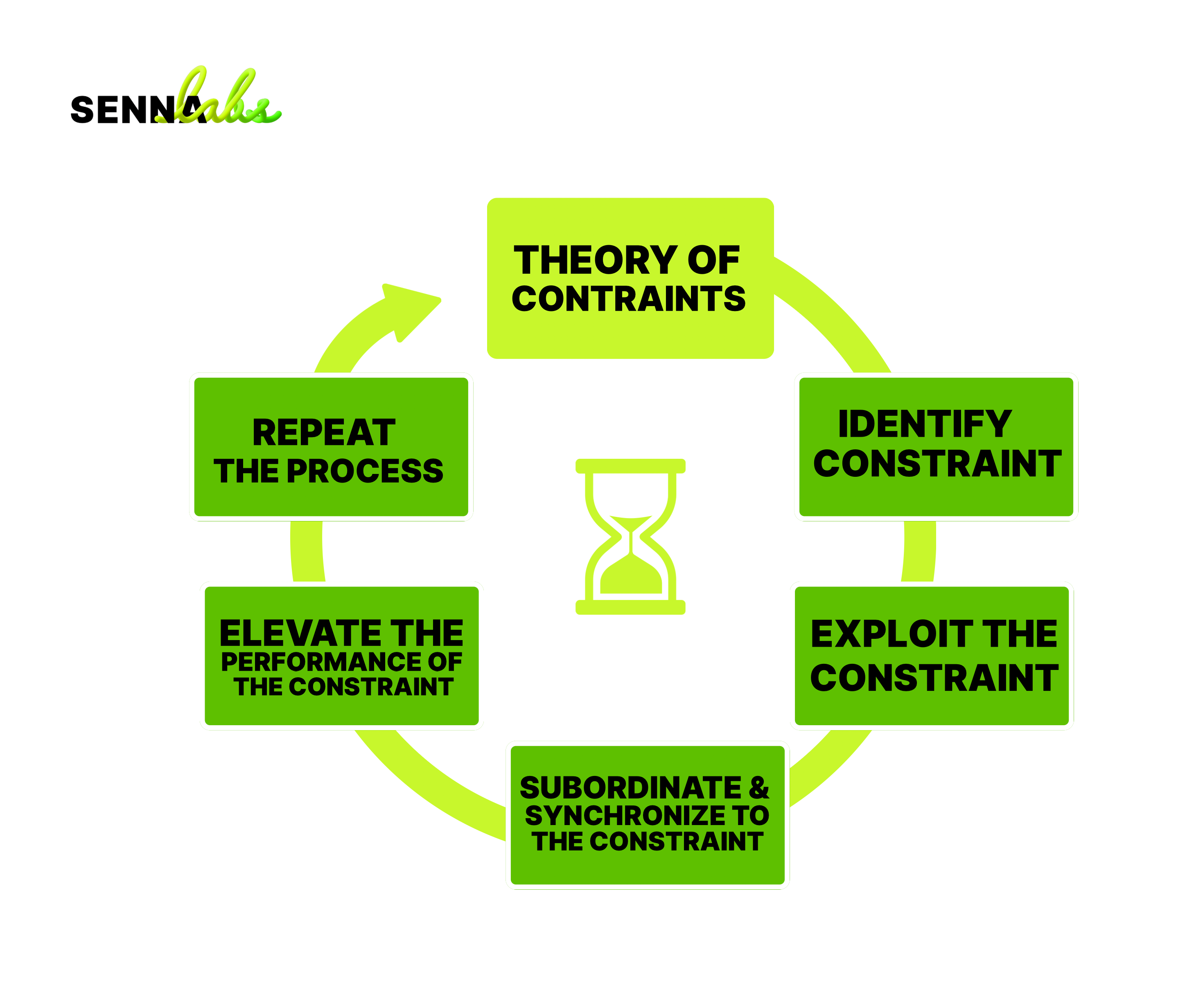

This is the essence of the Theory of Constraints, developed by Eliyahu M. Goldratt in The Goal.

A system’s performance is limited not by how well it works overall, but by its weakest link.

The challenge?

Most businesses don’t know where their weakest link is.

So they fix the wrong thing — they hire more people, buy more software, reorganize departments — and still feel stuck.

To really move forward, you need to first identify the true constraint.

What Bottlenecks Actually Look Like

They’re rarely dramatic.

You won’t see flashing alerts or red flags on your dashboard.

Instead, you’ll feel them:

-

Decisions take too long — no one owns them, or too many people do

-

Handoffs break down — things sit idle between teams

-

Work gets patched manually — extra steps are added just to keep things moving

-

Tasks get repeated — because expectations weren’t clear the first time

Your team works hard. But the system is leaking energy.

That’s the bottleneck.

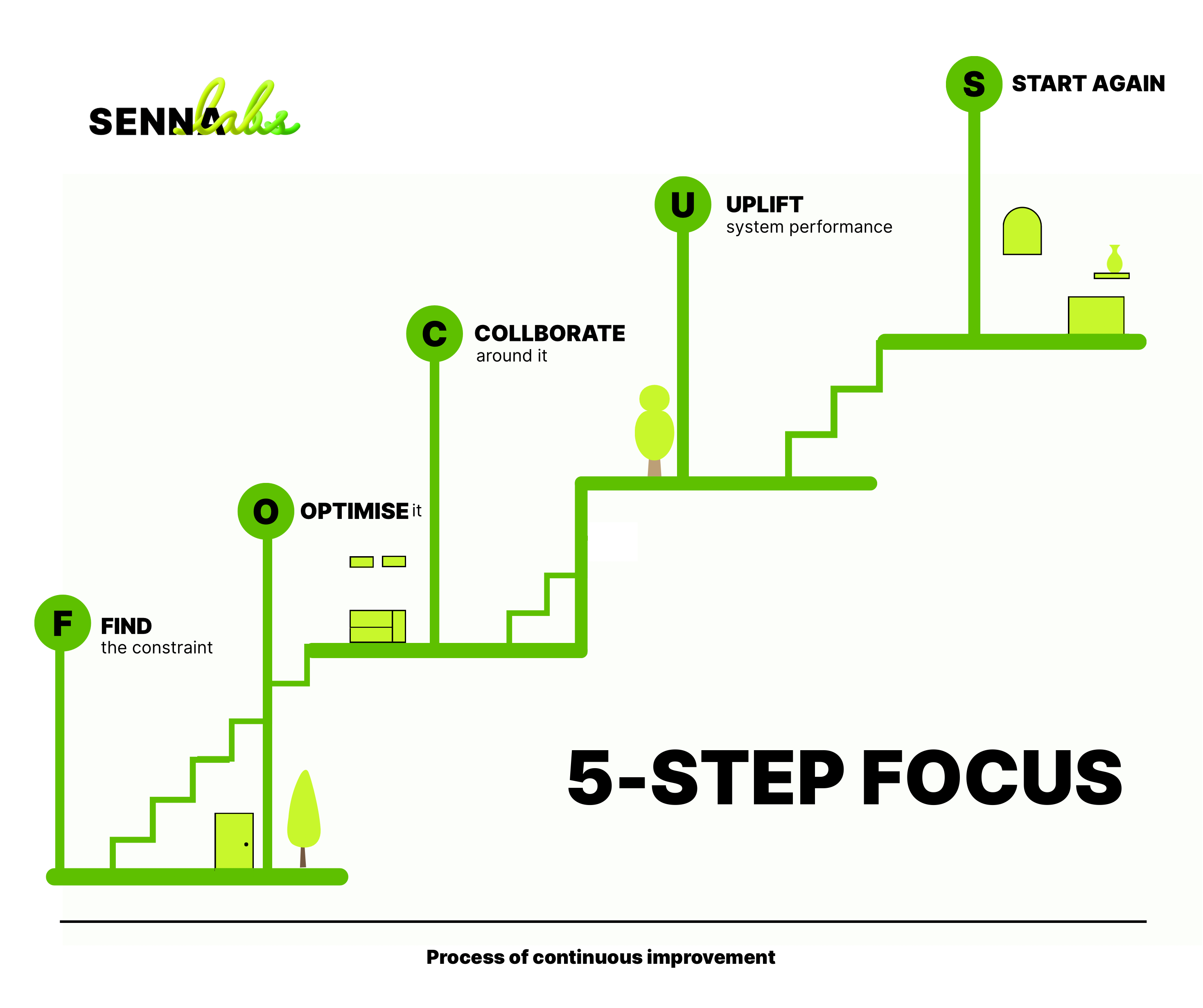

How We Fix It: The 5-STEP FOCUS Model

At Senna Labs, we use a practical method inspired by the Theory of Constraints.

We call it the 5-STEP FOCUS — and it’s how we diagnose and solve systemic issues without unnecessary complexity.

Here’s how it works:

F – Find the Constraint

We start by mapping the actual process — not what’s on paper, but what really happens.

We use the Senna Labs Bottleneck Reflection Canvas to identify where things slow down, pile up, or get unclear.

We look for:

-

Delays in approval

-

Confused ownership

-

Over-reliance on specific individuals

-

Lack of shared visibility

O – Optimise It

Once the constraint is clear, we look for the smallest meaningful change that can improve it.

This might be:

-

A dashboard to surface blind spots

-

An early-warning system

-

Workflow automation

-

Reassignment of ownership

We don’t overbuild. We fix precisely.

C – Collaborate Around It

We align the teams affected. Everyone needs to understand the constraint and agree on the fix.

This could mean:

-

Process redesign

-

Cross-team planning

-

UX-led product scoping

-

Shared rituals and expectations

No solution works unless everyone collaborates around it.

U – Uplift Performance

With the fix in place, we monitor system-wide impact:

-

Are things moving faster?

-

Are people making fewer manual corrections?

-

Are we seeing fewer exceptions?

This is often when teams feel a wave of relief — they can finally focus again.

S – Start Again

As soon as one constraint is fixed, another will eventually emerge. That’s normal.

It’s how healthy systems evolve. We repeat the process — focused, calm, and continuous.

Case Study: A Global Tire Manufacturer

One client we worked with is a leading global manufacturer of tires for cars and industrial vehicles.

They were missing production targets — despite having great people and solid tools.

At first, they assumed the issue was miscommunication or general inefficiency.

But when we used our Bottleneck Reflection Canvas to map their process, the real issue became clear:

They were constantly running out of key raw materials — and no one had an early-warning system in place.

Procurement knew when stock was low. Production teams only found out too late.The delay was caused not by people, but by a lack of shared visibility.

So instead of a full system rebuild, we created:

-

A real-time dashboard showing live material levels

-

Automated alerts when inventory dropped below thresholds

-

Shared access across procurement and production

The result?

Delays dropped. Planning improved.

No major overhaul required.

Just clarity — and a system that could see what mattered.

What You Can Do First

If your growth feels slower than it should, don’t start with a new system.

Start with a better question: Where is the actual constraint?

Here’s how to begin:

-

Map what’s actually happening in your process

-

Spot where things slow down, loop, or rely on people remembering

-

Identify the real limiting factor

-

Design a focused, system-level fix — not just a surface patch

Subscribe to follow product news, latest in technology, solutions, and updates

บทความอื่นๆ

Let’s build digital products that are simply awesome !

We will get back to you within 24 hours!ติดต่อเรา Please tell us your ideas.

Please tell us your ideas.