Reducing Workplace Errors with AI-Powered Quality Control

Share

In industries like manufacturing, where precision and efficiency are paramount, workplace errors can result in wasted materials, increased costs, and diminished customer satisfaction. Traditional quality control methods, often relying on manual checks, are time-consuming and prone to human error. Enter AI-powered quality control, a transformative solution that leverages advanced technologies to ensure consistent quality, detect defects in real-time, and minimize waste.

This article explores how AI is revolutionizing quality control, focusing on a use case where a manufacturing company integrates AI to monitor production lines and enhance efficiency.

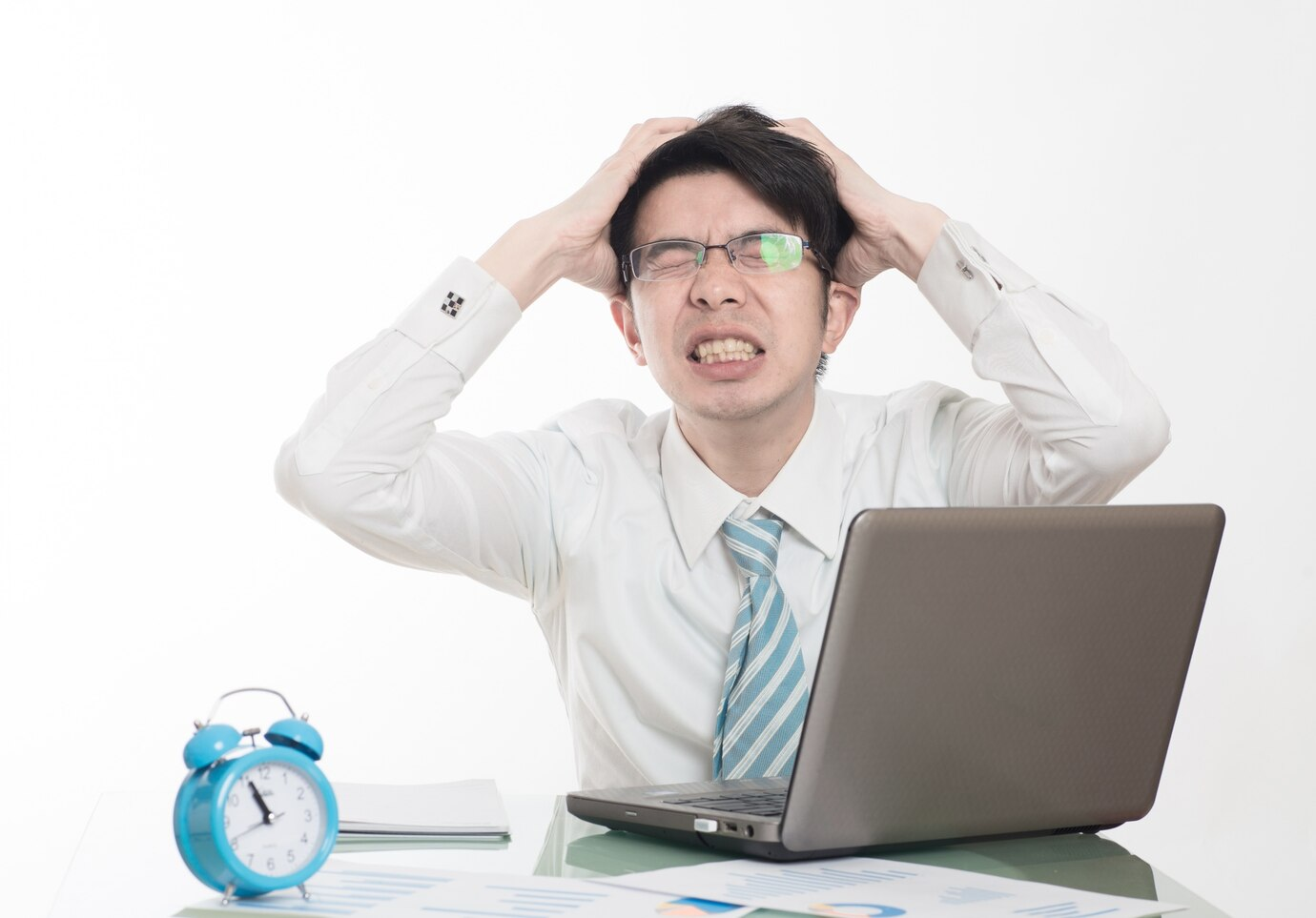

The Challenge: Traditional Quality Control Methods

Manufacturing operations face several challenges in maintaining quality:

-

Human Error: Manual inspections can miss subtle defects, leading to inconsistent product quality.

-

Delayed Detection: Flaws identified late in the production process result in wasted materials and rework.

-

Scalability Issues: As production scales up, traditional quality control struggles to keep pace.

-

High Costs: Quality-related issues, including recalls or repairs, significantly increase operational expenses.

These challenges demand a smarter, more efficient approach to quality control.

How AI-Powered Quality Control Works

AI-powered systems combine computer vision, machine learning, and real-time data analysis to detect defects and ensure quality throughout the production process. Here’s how they function:

-

Real-Time Monitoring:

-

AI systems use cameras and sensors to monitor production lines continuously.

-

They analyze product dimensions, surface textures, and assembly accuracy in real-time.

-

Defect Detection:

-

Machine learning models identify defects, such as cracks, dents, or misalignments, with high precision.

-

AI systems flag defective items instantly, ensuring they are removed from the production line.

-

Predictive Maintenance:

-

AI tools analyze equipment performance data to predict potential failures before they occur.

-

This minimizes downtime and ensures smooth operations.

-

Process Optimization:

-

By analyzing production trends, AI identifies bottlenecks or inefficiencies, recommending adjustments to improve workflow.

Use Case: AI in a Manufacturing Company

A manufacturing company integrates AI-powered quality control into its production process. Here’s how it works:

Step 1: Monitoring Production Lines

-

Cameras and sensors installed on the production line capture detailed images and measurements of each product.

-

The AI system compares these inputs to predefined quality standards.

Step 2: Identifying Defects

-

The AI detects a batch of products with surface defects caused by a calibration error in a machine.

-

It immediately notifies the production team and removes the defective items from the line.

Step 3: Predicting Equipment Issues

-

The AI system identifies unusual vibration patterns in a key machine, indicating potential wear and tear.

-

Maintenance is scheduled proactively, preventing a breakdown that could disrupt production.

Step 4: Optimizing Processes

-

AI analyzes data from previous production cycles, identifying steps where materials are overused.

-

It suggests adjustments, reducing waste and cutting costs.

Benefits of AI-Powered Quality Control

-

Consistent Quality: AI systems ensure every product meets the same high standards, boosting customer satisfaction.

-

Real-Time Defect Detection: Instant identification of defects minimizes waste and rework costs.

-

Enhanced Efficiency: Automated monitoring reduces the need for manual inspections, freeing employees to focus on other tasks.

-

Cost Savings: Early detection of issues and optimized processes reduce material waste and operational expenses.

-

Scalability: AI systems handle high production volumes without compromising accuracy or speed.

Broader Applications of AI in Quality Control

While this use case focuses on manufacturing, AI-powered quality control is transforming other industries as well:

-

Pharmaceuticals: AI ensures precision in drug manufacturing, verifying dosage accuracy and packaging integrity.

-

Automotive: AI systems inspect vehicle parts for defects, ensuring safety and reliability.

-

Food Processing: AI monitors food quality, detecting contaminants and ensuring compliance with safety standards.

-

Electronics: AI inspects circuit boards and components for flaws, improving product reliability.

Challenges and Solutions

Despite its benefits, implementing AI-powered quality control comes with challenges:

-

High Initial Investment: Setting up AI systems and integrating them with existing processes can be costly.

Solution: Start with pilot programs to demonstrate ROI before scaling up. -

Training Data Requirements: AI systems need large datasets to learn and perform accurately.

Solution: Use simulated data or partner with vendors specializing in AI training models. -

Integration Complexity: Integrating AI tools with legacy systems may pose technical challenges.

Solution: Work with experienced AI providers to ensure smooth implementation.

The Future of AI in Quality Control

As AI technology advances, its role in quality control will expand, introducing new possibilities:

-

Self-Learning Systems: AI will adapt and improve over time without requiring manual updates.

-

IoT Integration: Connected devices will provide real-time data, enhancing monitoring accuracy.

-

Sustainability: AI tools will help companies reduce waste and energy consumption, aligning with eco-friendly goals.

-

Universal Standards: AI-driven quality control systems will standardize production across global facilities.

Conclusion

AI-powered quality control is transforming industries by ensuring consistent quality, reducing workplace errors, and minimizing waste. For manufacturing companies and beyond, AI tools bring speed, accuracy, and efficiency to quality assurance, enabling businesses to meet high standards and maintain competitiveness.

As organizations continue to adopt AI-driven solutions, the future of quality control promises to be smarter, faster, and more reliable. Embracing AI isn’t just about improving processes—it’s about setting new benchmarks for excellence in every product and service.

Share

Keep me postedto follow product news, latest in technology, solutions, and updates

Related articles

Explore all